Turnkey project

Greenhouse Project

ORGIL-PROFILINE -GREENHOUSES

ORGIL-PROFILINEGreenhouses Agriculture consulting is global company based in USA & ISRAEL and is recognised as one of the world’s leading manufacturers and developers of complete greenhouse agricultural growing systems.

ORGIL-PROFILINEhas gained a “can do” tradition with an unmatched expertise in the development, manufacture and installation of highly specialized controlled environment agriculture systems around the world.

Our primary mission is to develop economically viable agricultural infrastructure projects that enhance the quantity and quality of agricultural production.

In addition, the company provides on–location training, long term follow-through, and market research and feasibility studies where necessary

ORGIL-PROFILINE roots were established 40 years ago in Israel as one of the country’s original greenhouse manufacturers. Israel is a small country with limited agriculturally-productive land, limited water resources; yet Israel is universally admired as an agriculturally productive country and a net exporter of agricultural crops.

This has been achieved through the innovative development of greenhouses for the production of high-end horticulture and floriculture crops for both domestic consumption and export to European markets.

By building low-cost greenhouses using galvanized steel frames, poly skin, drip irrigation, shade nets, insect nets, and proper ventilation mechanisms, farmers are able to control the environment (temperature, humidity, light…etc..) allowing crops to reach near maximum potential (an impossible quest in an open-field

Environment); this has created a number of undeniable advantages

1.1 GREENHOUSE STRUCTURAL

Our greenhouse is design for growing all year-round all kind of vegetables and flower.

we offer all necessary materials design and system suit for the standards required for

Greenhouse structure.

The greenhouse is covering with Plastic on the roof and side lateral Balcony. curtain plastic on the front has walls.

The greenhouse is made of metallic galvanize material; all structure is bolted with no need of welding on the installation area.

Our Climate control systems – includes heating, thermal screen and circulation fans.

Computerized central control system

Trellising system suit for agro technique that enable the crop to be freely interchangeable Greenhouse

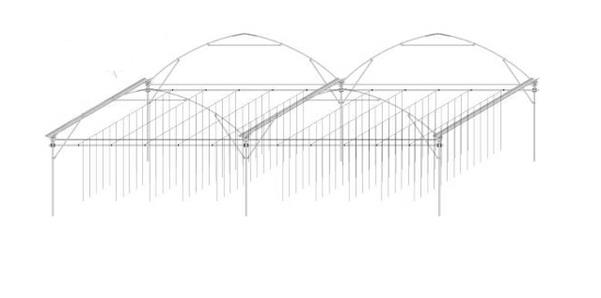

SKELETAL STRUCTURE

The greenhouse frame is fabricated from galvanized steel. ORGIL-PROFILINE use galvanized round tubes and Close profiles to ensure longevity and sustained structural integrity. These unique tubes and profiles are used to build the major components of our greenhouse frame, foundations, poles and arches.

The Metalic Structure is Calculated for the flowing Loads :

120 kmh wind load

30kg trellesing crop load

0.25k/N snow load consediring that the structure is heated and snow won’t acumelted on the structure

TECHNICAL DATA

All tubes, profiles, brackets, bolts and nuts are galvanised with zinc, all sizes are nominal’s

FOUNDATIONS: the foundations are made of “O” Tubes 3″ x (=”O” 89 mmX2.5mm), to be cemented in the field according to the engineering design with 0.08 m3 concrete B200 per unit = (200 kg cement for one m3 concrete)

COLUMNS: are made of “O” Tube 3″ x (= “0” 89 mmX2.5mm ) 4.3 m for 4.5 m gutter high.

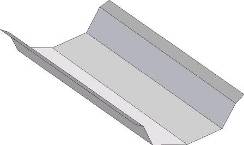

GUTTERS: Hot deep galvanized steel gutters are designed to make moving around during construction or film replacement easy and to aid rain water run-off. The gutters have the benefit of an extra protection against corrosion compared with the rest of the structure.

REINFORSEMENT: according to the design; made of 1.5” (48mm), 1″ (32mm) pipe.

2” (60.3mm) and 3/4 “ (27mm)

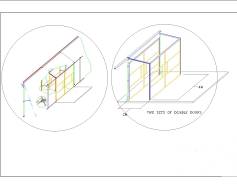

CORRIDORS on gutter sides, 2.5m width, made of galvanized “Close profile.” 80 x 40X2.5mm

CABLES: 5 mm as and when needed, according to the engineering design.

DOORS: 2 entrance , located on gutter fronts . doble door with a 4m sterile room between them . Door dimention: 2 wing of 2m width on 2.5m hight total of entrance opening 4m .The doors are sliding type with brushes built of alumnium frame with double layer transparent polycarbonate.

1.1.1 TRELLESING SYSTEM

For growing Vegetable a trellising system is needed. We are offering truss support build from 3” pipe with 2” support including 5mm cable every 4m to support the 3mm wire,

We will supply in 12 line of 3mm wire per bay.

1.2 DRIVE SYSTEM

1.2.1 LATERAL VENTILATION

During Cold weather,when all curtain are close the temperature inside the greenhouse on the night can be maintained within a degree or two of outside temperature if no heating system is ussing .

On cold weater Energy costs are reduced By closing the grenhouse vent preventing from the hot air from goint out .on the day when there is sun the curtain can be roll up letting dry fresh enter the greenhouse .

Adding side vents allows cooling and air movement when there is no high winds or rain

Every vent has its independent mechanism, with its own geared motor that can be operate separately.

Side Vent ventilation

Our ventilation system is built from Rw45-5 gear motors with siliding telescope .The opening vent can be automatically opened by controll system according wind load . each Vent can be controoled independly .

Vents technical description :

The motors are EU product only on front walls

Each side motor is connect to 2 SC40 –sliding cardan that give long operation life.

1.3 HARVEST EQUIPMENT

Trellising reinforcement are installed along each of the structural front gable in order to support the weight of the trellised crops .The system is built from adustuble tube bars, tube support and 5mm cables.

Necessary parts and equipment will be supplied for an efficient and smooth trellising work for vegetable. This equipment Reduce plant damages by workers while trellising the crop.

Plants can be lowered according its development, workers are always picking at same level without need of lifting equipment or workers.

The equipments included:

25,000 per Ha of greenhouse Crop hanging device composed of hanger with 12m of rope allowing lowering the crop as it grows. IS INCLUDED

100,000 per HA of greenhouse Plastic clips to tie the crop stem to the rope

1.4.1 Roof covering

Plastic film we ofer a first class plastic cuality thet can includ E.V.A IR AF DF from 150mic – 200mic .

-UVA Additive to protect poly sheets from decaying because of UV radiation. Offered material is warranted to keep its optical properties at least 4 years.

– Light transmission: possesses the highest light transmission –over 90%LT.

-Anti drip additive on inner face: The anti-dripping effect prevents the formation of droplets on the film thus improving light transmission and reducing the incidence of certain diseases.

In a very cold area we can ofeer Double Poly for beter isloation

1.5 MOTOR/BLOWER INFLTED SYSTEM

For the propose of inflating the plastic we are offering independed inflating system , each roof will have two motor blower that will seat on each side of the gable front..

The motor blower is made of aluminium and produce in Italy

- Our centrifugal blowers provide high pressure and high flow rate air stream from an essentially square outlet.

- The air outlet is normally flanged with holes for easy fastening to any duct.

- The suction side has a curved nozzle for maximum efficiency and noise reduction

- The sturdy housing construction allows good resistance to strains

Insect net protecting

50 mesh insect net in all lateral vents

The insect net function is prevent insect form entering to the greenhouse and reducing white fly qty inside the greenhouse .this insect net is reducing ventilation.

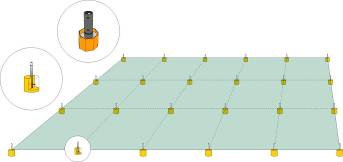

1.6 HYDROPONIC SYSTEM

Our offer for hydroponic system we are offering channel system that lay on the ground

We can offer a system with channel above the ground if needed.

Growing Crop on artificial substrate for better and easier management and control.

Rooting: roots are spread and not confined to a limited area. They can seek and share water and fertilizers all over the trough space.

Climate and humidity conditions: better aeration, temperature moderation and humidity circulation.

Sterilization: it is easy and safe to sterilize the substrate.

Replanting: the previous crop is easily removed and new plants can be planted after sterilization.

The growing substrate system is base on troughs and coconut fibber substrate grow-bags.

Coconut fibber substrate, of the best international quality, duly disinfected in ready to use grows bags. Compressed fibber is already wrapped in polyethylene bags, ready to be posed in the troughs. Substrate grow-bags hold on polypropylene troughs, 700 micron thick, black colour, UV stabilized, high chemical resistance .The troughs are easy to assemble, resistance to steam sterilization and 5 years warranty.

For better drainage, troughs are supplied with spacer.

For the Vagtbale we are offering 6 row of 20x16cm of growbeg for 8 Ha

For 2 ha we are offering 14 row of 45 cm of growbeg built of 3 growbag of 15cm on 7cm

1.7 IRRIGATION AND CONTROLL SYSTEM

1.7.1 Irrigation system

The irrigation system is designed in accordance with the daily water requirements for vegetable cultivation (6mm/day=100m2/for the entire cultivation area, summer time)

6 rows per gabble, with 1 drippers line each, 12mm diameter, 20 cm between drippers.

Main drippers of the “ on line” type , , self compensated no drain .

The irrigation system works together with the fertigation system and includes all of the components required for proper operation, including pipes, filters, valves and pumps. it is also equipped with the units for connecting to the operative tank located in the main energy Center

The picture is for illustrated only

1.7.2 Control system

All the supplementary system operating in the greenhouse is computerized .The control system will control, command and follow up all the functions of the project .All the system can be operated in two ways:

Automatically operated by the central control computer unit, according chosen program.

Manually, thru the central computer unit or from the electrical board in the greenhouse.

This system is based on the following properties:

Digital controllers at the greenhouse level, one unit in each greenhouse.

A central computer unit pc will command, control, follow up and store historical data of the entire project. Connected by wire to the greenhouses, for more reliability (UN wires is optional if requested). Included programmable alarms. Remote access is available by modem of internet.

Functions to be controlled :

Thermal screen, operated by temperature. Radiation and heating function.

Circulation Fan: operated by temperature and humidity.

50’ Fan : operated by temperature and humidity

Heating system: controlled by temperature. The central control system gives the on /of operation, while the heating system operates the flow regulation according the heating demand of the greenhouse. .

Irrigation: full programming, control and operation from the central computer.

Fertilization table: for automatic injection of fertilizers into irrigation water .based on a by –pass system, with its own electric pump. Venturi pumps inject the fertilizers stored in open plastic tanks .All function controlled from central computer.

Ec/Ph controller: the fertilization table has it own EC/PH controller, connected to the central computer. Can be operated from the table itself of from the central computer.

Sensors:

Temperature and humidity sensors –wet-dry ventilated cell. 1 unit per 5000Sqm

Sun radiation, from the central meteorological station.

Central Meteorological Station.

Wind speed :Range 0km/h to 280 km/h ,resolution :1km/h, measurements recorded every 2.25 seconds , accuracy +/- 5%

Wind direction sensor: Range 0 to 360 degree , resolution of 1 degree, measurements at intervals of one second .Accuracy +/- 7%

Solar radiation sensor : spectral range :400-1100 nanometres , percent a full scale :+/- 2%

Rain Meter : resolution :minimum quantity of 0.2mm .Accuracy: +/- 4%

Temperature /humidity meter

Snow Melting

1.7.3 Irrigation Water storage tank

8 tanks of 250 m3 Central water tank-made of metallic structure (9.1m diameter3.12 height)

8 tanks of 1000 litter Fertilize tank made of plastic –Rotoplast

1.7.4 Drainage Disposal system.

About 30% of used water and fertilizing are eliminated as the effluent of the substrate growing system. This amount of water can be used for any alternative open field crop

Disposal: this alternative means disposing off a valuable input, of fertilizer and water

We are offring a water drainage system that will colect the drainage water from each

Growbage line to a beried tank at the edge of the greenhouse from there a pump will push the water 20m away from the greenhouse

1.8 HOT WATER HEATING SYSTEM AND CO2 CONDENCER.

1.8.1 Hot Water heating system

The optimal temperature for vegetable production range is between 12-18 degree.$

In a climatic area when the temp can rich -18 degree.

We recommended using hot water system with snow melting system to insure snow won’t accumulate on the structure.

Our calculation is for DT of 25 degree considering 30% saving only

Our offer is include: compleate heating system eith co2 condencer to increase yield

The customer will supply natural Gas to the entrance of boiling area

For the main heating system we will supply 4 Boilers of 4 million Kcal each all boilers will be located in one place and will back up each other.For backup system we will offer Dual Burner that work on gas and diesel . In case of a problem with the main gas supply the burner can be switch immediately to diesel.

Main incoming and outgoing manifolds that will be mounted localy ,.

All necessary pumps and valves, ready for connection to heat dispersion system in the greenhouse..

Command board included, to be connected to the central control system.

Insulated steel pipes for hot water conduction to the greenhouse and back to the boilers’ room. Pipes painted for better protection against corrosion.

Heat diffusion system.

Main hot water heating system by

Snow melting system by fin pipes below the gutter.

Irrigation water heating galvanized fin pipes, on each growing line the path between the growing row will remain clean for clean passage system: water from well, normally arrive at about 5 degree in such cold winter countries. It has to be heated to about 20 degree.

We are supplying heating system for DT of 20 degree. We are considering that the water tank will be inside a facility from preventing the water to drop below zero

The electrical current required for feeding the electricity panel in the boiler room is about 3×380-480a (a final numbers will be present with orders)

All heating calculation are base on that SLS Hermoney 40% high quality by svensson(netherland) thermal screen will be installed and 40%-47% of heating energy will be saved

The net will provide 40% of shade during the day .with 60% of light diffused

1.8.1 CO2 Condencer

Plants absorb CO2 from the surrounding air through the pores in the leaves.

Inside the leaves, carbon dioxide is transformed into sugars and other carbon-containing substances.

CO2 uptake and the forming of sugars is known as CO2 – assimilation or photosynthesis.

Because this process requires light as the source of energy, CO2 is taken up only at day time.

The carbon-containing products formed in the assimilation process are called assimilates.

They are used together with mineral nutrients and abundant water to build the plant tissues and organs.

Therefore CO2 uptake is the basis of plant growth.

When there is no CO2 supply and insufficient air refreshment in the greenhouse, the plants may consume more CO2 than comes into the greenhouse.

This makes the CO2 drop to a level below the normal outside level of 340 ppm.

Such a condition with a lower-than-outside CO2 concentration in the greenhouse is called CO2 depletion.

If the CO2 level is as low as 200 ppm, photosynthesis is reduced to only half the photosynthesis rate at the normal CO2 level of 340 ppm.

CO2 depletion causes the plants to be unable to utilize the good light conditions, and when this situation lasts longer, growth and production will drop dramatically.

In our offer we will include condencer on the bolier room taht will use the co2 that as been create from the gas burning and we will distribute it alond the greenhouse to increase Co2 ppm level .

1.9 SUPPLEMENTAL LIGHTING

Supplementary lighting is designed to provide general illumination to give you enough light to work when it is going dark, as well as contributing a little towards supplementing natural daylight or artificially increasing day length during the winter or spring. Growing lighting, by contrast, is specifically intended to bring on plants – often being used to “force” them to flower out of season. As a result, it is typically more sophisticated and the quality of light produced is much more closely controlled than you need simply to avoid stumbling in the dark

This system assumes a light intensity according the need of the different crops.

Proposed lighting plan gives enough light for full production even in the middle of the winter.

- Reflector: specially designed reflectors, made of high quality anodized aluminium, with special polish for a better and uniform light distribution .its special geometry allows this reflector to be located close to the crop and still having a uniform light distribution. Meeting CEE standards.

- Lamps: Lamps is of European or USA production .These are special lamps designed for horticultural crops lighting. Their spectrum in the photosynthetic range allows a maximum efficiency and energy saving. These lamps have an energy consumption of 400/600 watt/hr.

- Ballast: All electrical components are of the EC origin. Ignition system will be of the magnetic type (not electronic), more suitable andreliable for system with variations in the voltage of the electrical supply.

- Lighting plan: we recommended the flowing light intensity: 24 watt lamp has 2,000 lumens.

- For Vegetable: 1600 lamps -Fixtures will operate on 480 vlots. installed.(about 8000-9000lux)

- These values have to be confirmed when reliable data on natural sun radiation intensity will be available.

- Lamp distribution: mounted on 6 rows /gable in trellised crops.

- Lamps of 600watt/480v

- Electric Board and Cable system

1.10 THERMAL SCREEN

We are offering a thermal screen SLS 40% Hermoney. (Product of Svensson Netherlands)

Operated by the “wire system”

The Energy shade thermal screen can shade on high radiation .40%-47% energy saving factor for night heating .

Special weft allowing water vapours to pass thru

Screen opening and closing along 4m dimension

Protection against harmful U.V radiation

Manufacturer’s warranty against U.V radiation for period of 5 years.

The thermal screen can be operated day and night for heating energy saving

RW803 with position indicted .1 motor per 5000 sqm .

1.11 SOIL MULCH

Black and white water permeable Polyethylene cloth ,135 gr/m2 on all surface .

Avoids weeds to grow.

Water permeable

White colour reflects the light, for better condition in the greenhouse .

1.12 CIRCULATING FANS-

The fans in hot time pushing hot air outside the greenhouse thru frontal lateral vents homogenizing the air by removing the hot Humidity bubble from the greenhouse center.

Air movement gives a better crop (Static air can cause diseases like botrytis, etc.)

The use of vertical fans can save energy in case of higher heat demand because the warm air in the upper part of the greenhouse can be mixed with the cooler air in the lower part of the greenhouse.

The use of fans creates an equal temperature in the greenhouse and to prevent temperature differences which results in a higher uniformity of the crop.

The use of fans prevents condensation on the crop. In the evening the humidity gets on the crop which can cause botrytis, rotting, etc.

The use of fans offers a 100% solution in regards of uniformity of blooming of flowers.

The micro climate around the crop is improving due to the use of fans; less humidity and less sensitive for temperature changes

The fans avoiding humidity to deposit on the plant homogenizing temperature while heating .

The fans moving air the prevent frost.

The fans operated by independent Group sections by central control .

We are offering 18” fans One-phase motor.

Fans operated by independent sections by central controll system, according the needs.

We offer 68 units for each greenhouse block

1.13 50” FANS

The fans in hot time Pulling hot air inside the greenhouse thru frontal lateral vents and replacing it with less hot and humide air from the outside.

The fans operated by independent Group sections by central control .

We ahve fonded that at cold area when there no meny sanny days and cold temp can be for long period

A passive ventelion will make it difficult to controll the humidation in the greenhouse and will waste alots of energy while active ventilation with 50” fan alowing the grower reduce humdty in the greenhouse even if there is only half an hour of sun .

We are offering 50” fans tri-phase motor.

Mounted inside a galvanized metal cylinder for better air conduction .with chains for hanging ..

Florida

743 Villa Portofino Circle

Deerfield Beach, FL 33442

Tel: USA + 1-619-9137771

info@orgil-profiline.com

California

2168 Balboa Ave, Ste 3

San Diego, CA 92109 USA

Tel: USA + 1-619-9137771

info@orgil-profiline.com

Office Hours

Mo-Fr: 8:00-19:00 ET

Sat & Sun : Closed